| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SUNWAY |

| Model Number : | SILOS |

| Certification : | CE,AISC,ISO,JIS,CWB |

| Price : | USD 1050-1200 TON |

| Payment Terms : | T/T |

| Supply Ability : | 10000 ton per month |

| Delivery Time : | 30DAYS |

![]()

We specialize in integrated processing of heavy steel structures for bridge girder erection machinery, providing customized manufacturing services from precision components to complete assembly for large equipment like ship loaders and construction cranes. Our processes combine laser cutting (±0.5mm accuracy) and plasma cutting (up to 150mm plate thickness), supported by 6000kN 3D CNC press brakes and 100mm plate rolling systems for complex-shaped structural forming.

All load-bearing welds undergo 100% ultrasonic testing (UT) and magnetic particle inspection (MT) per AWS D1.1/D1.5 standards, with laser 3D scanning verifying box girder straightness (≤0.1mm/m). Surface treatment options include abrasive blasting (Sa2.5 per ISO 8501-1) with epoxy-polyurethane coating or hot-dip galvanizing (≥85μm zinc layer, ISO 1461 compliant), meeting ISO 12944 C5-M corrosion protection requirements.

Utilizing 2-axis machining centers and smart material traceability systems (EN 10204 3.1), we've delivered critical bridge equipment components including 80-ton box girders and high-strength steel joints, achieving 98.6% quality compliance with 30-day average lead time reduction. Our solutions comply with EN 1090-2 EXC4 standards for heavy steel bridge structures.

| Products | Engineering Equipment Feeder Processing |

| Main Material | Q235B(ASTM A36,S235JR), Q355B |

| Drawing Design | AUTOCAD /SOLIDWORKS/TEKLA |

| Surface Treatment | Painting, Galvanized |

| Process-Cutting | Laser cutting, plasma cutting, flame cutting for intricate shapes |

| Forming | Rolling, and bending to meet complex structural designs |

| Welding | MIG, TIG, Submerged arc |

| Machining | Drilling, milling for precise fittings |

Competitive advantage

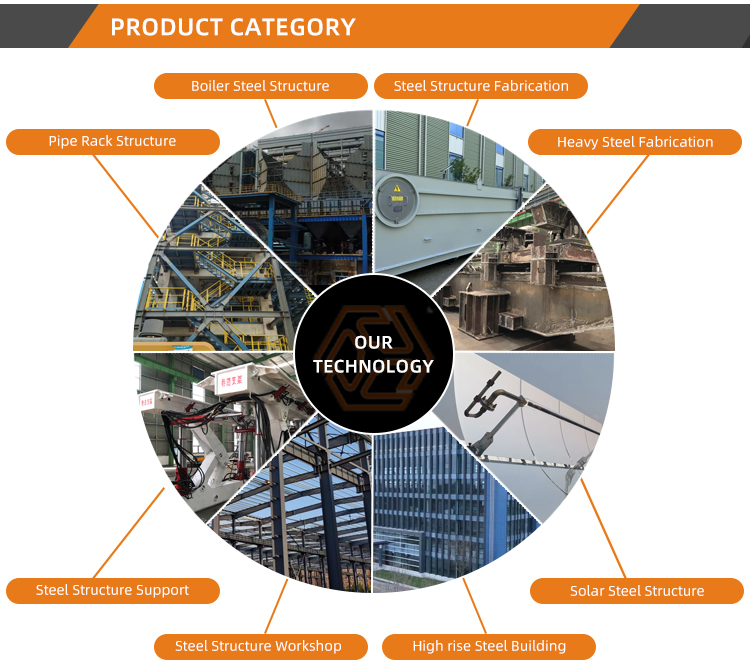

Besides the Automatic Intelligent Production Line for H beam & Box Column, Sunway is well equipped with PKG Synthetic cutting line, Laser Cutting Machine, Robot Welding Machine, Sawing Machine, Drilling Machine, Hydraulic Press Machine, Punching Machine, realize the scale and high-efficient production of factory intelligent manufacturing.

A customized MES system under developing, which combines TEKLA, Solidworks, and normal MES software to achieve centralized dynamic control of the entire process of order design, production, and erection,achieving full traceability of product component cycles.

SUNWAY introduce industry-leading 3D design software, which has powerful parametric design function and visual effect display. Through these software, designers can quickly build complex steel structure models, simulate structural performance under different working conditions, identify and solve potential problems in advance.

|